Robotics Automation is a very rapidly growing field. Since few years Industrial robots are very common in industries across the world. Day by day their popularity is increasing because of their higher productivity, suitability and also profitability.

Robotics brought a revolution in the industrial sector. The next move of the robots will be the change in the work. So we should keep an eye on what’s coming next because the robotics field is very vast and the use of robotics in the future is unpredictable.

Everyday robots help in improving the world through engineering.

Top Robotic Trends to Keep an Eye on

Robots will consistently help in transforming the manufacturing field in innumerable ways. Here are the 6 future trends which play a key role in Robotics Automation in the upcoming years.

1. Adoption of Industrial Internet of Things (IIoT) Technology

Day by day robots will increasingly utilize the smart sensors in the field of production to collect previously inaccessible data from the manufacturers. This way of collecting data is trending nowadays and going on very smoothly. Moreover, this also helps to gain higher productivity and profitability.

2. Industry Cyber security as a Priority

Due to the interconnection of robots with the internal systems for the data collection, Cybersecurity risks will also increase. To overcome this, manufacturers take strict actions against the malicious threat by addressing vulnerabilities in their processes. Therefore, manufacturers invest a lot of money to protect the system from cyber threats.

3. Big Data Analysis becomes a Competitive Differentiation

Robotics will play an important role in collecting the data. To collect and analyze the information, manufacturers will play a significant role on the factory floor.

4. Open Automation Architectures will be Implemented

As robotics is being popular and widespread in the entire world, there will be a need for open automation to grow. As positive and negative results of robots are only depended upon the integrated systems, large industries started work with industry organizations to produce standards and open documentation for improving the product computability and make robotic integration easier.

5. Virtual Solutions will invade Physical Processes

In the near future, Virtual Solutions will become an elemental part of industrial robots. Soon, virtual solutions will occupy the place of physical processes. For evidence of concept and offline programming, presently growing application is the virtual representation of the robotic systems.

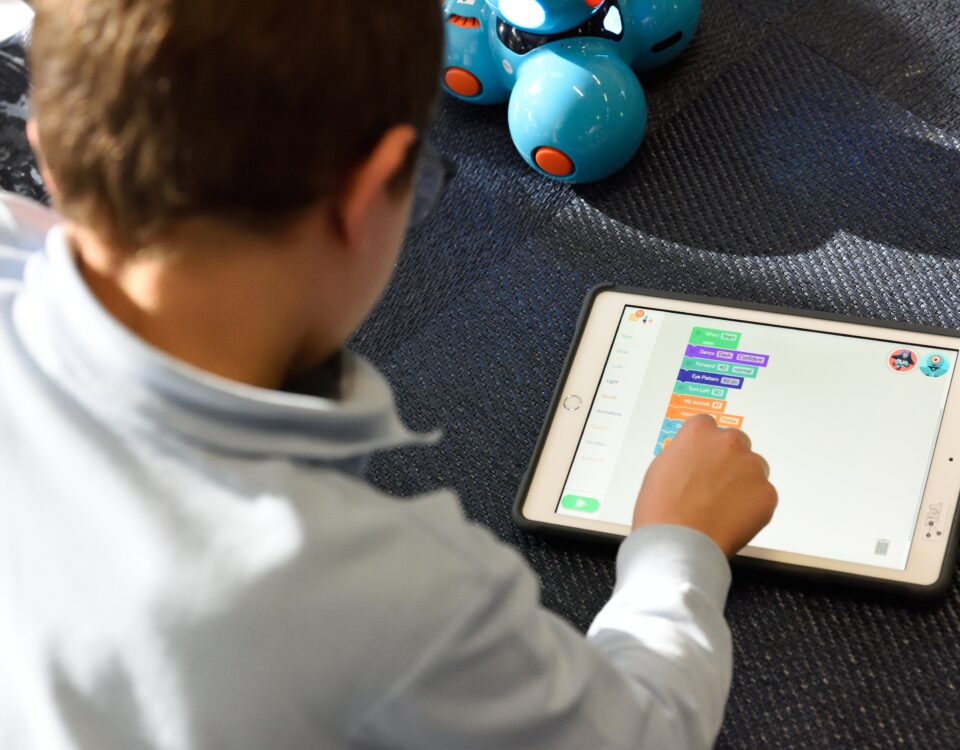

6. Collaborative Robots will consistent to grow in Popularity

The popularity of Collaborative Robots or we can say Cobots are continuously increasing day by day. Collaborative robots have countless benefits. They are also giving multiple benefits like reduced operational cost, safety, increased efficiency, reduced injuries and increased productivity alongside humans.

As compared to humans, robots complete certain tasks very faster, accurate and work 24*7 without work. Because of all those abilities, their popularity is at an extreme level in today’s world. A large number of manufacturers are adopting collaborative robots with precise ROI requirements because of their high ability to perform tough industrial tasks.

Robotic Automation has been a comprehensive technology in the manufacturing sector but still, it takes a couple of years to transform the industry. Moreover, the above 6 trends will be the undertaken in advance robotics course in the upcoming future of robotic automation.